Director and Scientific Coordinator: Dott. Ing. Ivan Giorgio

Activity

The Testing Laboratory on Materials and Structures of the University of L’Aquila, M&MoCS Research Center, is dedicated to experimentation on materials and structures for the purposes of applied research, teaching and consultancy for third parties.

The purpose of the Laboratory is to provide subjects in the construction sector with a diagnostic of the state of degradation of civil works, provide an assessment of the residual life of the structures and maintain them in safe operation through the use of optimal technologies.

The Laboratory is located in Via Le Prata, n. 10, Giuliano di Roma (FR).

Office Hours

| MORNING | AFTERNOON | |

| MONDAY | 8:30 – 12:30 | 14:00 – 17:00 |

| TUESDAY | 8:30 – 12:30 | 14:00 – 17:00 |

| WEDNESDAY | CLOSED | 15:00 – 17:00 |

| THURSDAY | 8:30 – 12:30 | 14:00 – 17:00 |

| FRIDAY | 8:30 – 12:30 | 14:00 – 17:00 |

Location

Via Le Prata 10 – 03020 – Giuliano di Roma (FR)

Tel: +39 334 5497381

E-mail: memocs.provemateriali@gmail.com

Equipment

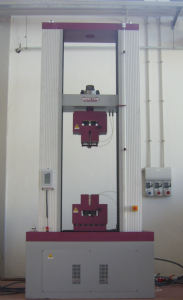

Testing machines, equipment and instruments fully comply with the regulations set down by Italian and European legislation .

Laboratory activities involve experiments on materials and structures for the purpose of consultancy, applied research and teaching.

Inside The Laboratory of Materials and Structures Testing compression tests are carried out on cubical and cylindrical concrete specimens, as foreseen by Law 1086/71 and as specified by UNI EN 2002 and EN 12390-7 12390-3 2003.

Furthermore, mechanical tests are performed on steels and other materials through the use of a universal machine able to perform compression, tensile and bending tests. These machines are controlled by automatically updated software that allows the performance of all tests in compliance with regulations.

Each test provides the issue of test certificates stating the results as required by the client, in full compliance with applicable laws.

Forms

- 2023 Laboratory Rules Code

- Brochure Structures & Materials Testing Laboratory

- Request and Certification Forms in accordance with the law 05/11/71 n. 1086, DM del 14/01/2008 (doc format)

- Request and Certification Forms in accordance with the law 05/11/71 n. 1086, DM del 14/01/2008 (pdf format)

- Price list

Banking Institute

BANCA POPOLARE DELL’EMILIA ROMAGNA – GRUPPO BPER

IBAN: IT08C0538703601000000198059

INTESTATARIO: UNIVERSITA’ DEGLI STUDI DELL’AQUILA M&MOCS – Centro Int.le Ricerca Matematica e Meccanica Sistemi Complessi